Emulsi VINNAPAS VAE dalam Aplikasi Pengemasan dan Pengolahan Kertas

December 24, 2025

Di bidang pengemasan kertas dan pasca-pemrosesan, stabilitas kinerja perekat secara langsung memengaruhi efisiensi produksi dan kualitas produk. Dengan meningkatnya popularitas sistem berbasis air di industri pengemasan, emulsi VAE secara bertahap menjadi pilihan utama untuk kotak kardus, karton kertas, dan kantong kertas karena kinerja keseluruhannya yang sangat baik. Seri emulsi VAE VINNAPAS, melalui variasi kandungan etilen dan desain formulasi, dapat mencakup berbagai aplikasi pengemasan kertas.

1. Karakteristik Teknis dan Keunggulan Utama Emulsi VINNAPAS VAE

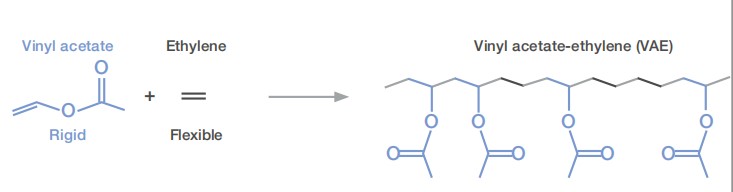

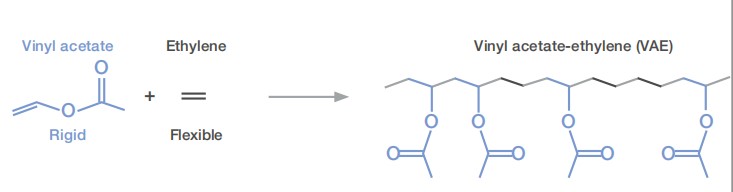

Emulsi VINNAPAS VAE adalah dispersi polimer berkinerja tinggi yang struktur molekulnya menggabungkan keunggulan vinil asetat (memberikan kohesi dan kekerasan) dan monomer etilena (memberikan fleksibilitas dan daya rekat). Struktur kimia yang unik ini memberikan keunggulan teknis inti berikut dalam pemrosesan kemasan kertas:

- Performa seimbang: Emulsi VAE mencapai keseimbangan yang baik antara kekuatan perekat, kohesi, dan fleksibilitas, sehingga memastikan kekuatan ikatan yang stabil pada suhu lingkungan yang berbeda.

- Daya rekat substrat yang sangat baik: Rangkaian produk ini tidak hanya cocok untuk kertas dan karton berlapis atau tanpa lapisan tradisional, tetapi juga memiliki daya basah dan daya rekat yang sangat baik pada berbagai "substrat yang sulit direkatkan" seperti film plastik.

- Kecepatan pengeringan yang sangat cepat: Pada lini produksi otomatis berkecepatan tinggi, kecepatan pengeringan secara langsung memengaruhi produktivitas. WACKER VAE memiliki kecepatan pengeringan yang sangat tinggi, yang dapat memenuhi persyaratan operasi berkecepatan tinggi dari peralatan pengemasan modern.

- Kemampuan pembasahan yang baik dan fleksibilitas pada suhu rendah: Bahkan dalam lingkungan bersuhu rendah, lapisan VAE dapat mempertahankan fleksibilitas yang baik, mencegah lapisan perekat menjadi rapuh, dan memiliki kemampuan penetrasi dan penyebaran yang sangat baik pada permukaan substrat.

2. Skenario Aplikasi Utama WACKER VAE dalam Pengolahan Kemasan Kertas

Penyegelan kotak dan karton kertas: Ini adalah area aplikasi paling umum untuk emulsi VAE. Baik itu karton lipat sederhana atau kotak kardus penahan beban, VINNAPAS memberikan daya rekat awal dan kekuatan akhir yang cukup untuk memastikan kemasan tidak terkelupas selama transportasi.

Kantong kertas, kantong dokumen, dan karung kertas: Dalam pembuatan kantong kertas, penyegelan bagian bawah dan pengikatan sisi membutuhkan perekat dengan kemampuan kerja yang baik dan ketahanan terhadap penuaan. Emulsi VAE (seperti VINNAPAS EP 705 A) memastikan kestabilan jahitan pada kantong kertas di bawah beban.

- Kardus bergelombang dan karton: Emulsi VAE umumnya digunakan dalam pengolahan karton bergelombang berkinerja tinggi, memberikan daya rekat dan ketahanan terhadap kelembapan yang lebih kuat daripada perekat pati tradisional.

- Aplikasi laminasi: Dalam proses laminasi kertas dengan film plastik (seperti PE, PP, PET) atau aluminium foil, emulsi VAE berfungsi sebagai dasar untuk perekat berkinerja tinggi, mengatasi tantangan pengikatan permukaan non-polar.

- Pengolahan karton lipat: Untuk kotak hadiah kelas atas, kotak obat, dan karton lipat lainnya, VAE memastikan bahwa lipatan tidak retak dan menunjukkan stabilitas mekanik yang sangat baik selama proses pembentukan.

3. Kepatuhan Lingkungan dan Jaminan Keamanan Pangan

- Keamanan kontak makanan: Emulsi VINNAPAS VAE memenuhi peraturan utama yang relevan untuk bahan kontak makanan dan cocok untuk pembuatan berbagai perekat kemasan makanan.

- Migrasi rendah dan tanpa plasticizer: Teknologi WACKER memungkinkan formulasi perekat tanpa plasticizer, yang memiliki karakteristik migrasi rendah, sehingga secara signifikan mengurangi risiko kontaminasi bahan kemasan terhadap makanan atau obat-obatan di dalamnya.

- Keberlanjutan: Beberapa model kelas atas, seperti VINNAPAS 920 Dan VINNAPAS EP 7000, tidak menggunakan APEO (alkilfenol etoksilat) dalam proses produksi dan memiliki kandungan formaldehida yang sangat rendah, sepenuhnya sesuai dengan standar produksi ramah lingkungan.

Situs web: www.elephchem.com

Whatsapp: (+)86 13851435272

Email: admin@elephchem.com